Panel fabrication continued

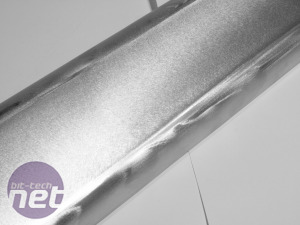

When the panels have been casted they come out with a very rough texture, which had to be smoothed out with a flap disc on an angle grinder, then finished with a Palm Sander and Wet & Dry:

Click to enlarge

Next I cut the top and front panel castings in half. I used a slitting saw on the milling machine to cut a straight line through the top panel, and a jigsaw to cut a pattern through the centre of the front panel casting:

Click to enlarge

Once each casting was in two halves I began fabricating various bits and pieces to go onto the panels, the first of which were some channels milled out, some SMD LEDs soldered and glued in place, and some hinges for the door panel:

Click to enlarge

Click to enlarge

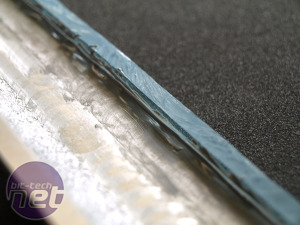

Some thin aluminium and acryllic strips were then very carefully milled out and glued to the cast panels using JB Weld:

Click to enlarge

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.